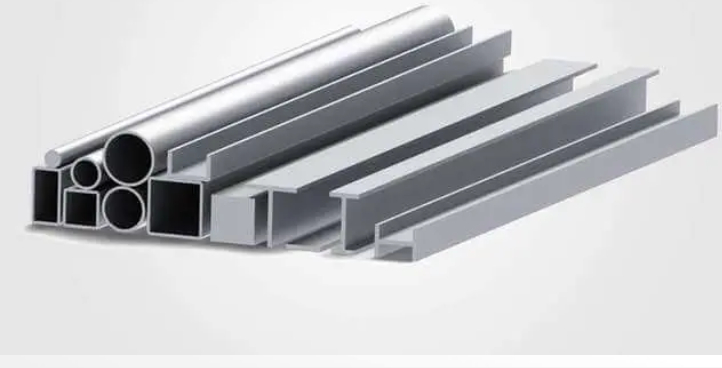

Aluminium extrusion is an industrial forming process that is used to produce long profiles of a constant cross-section. This cross-section is shaped by the opening in a steel tool known as a die.

Knowing where and how to make minor tweaks and changes will yield significant benefits, not only in extrudability but also with manufacturing and production costs too.